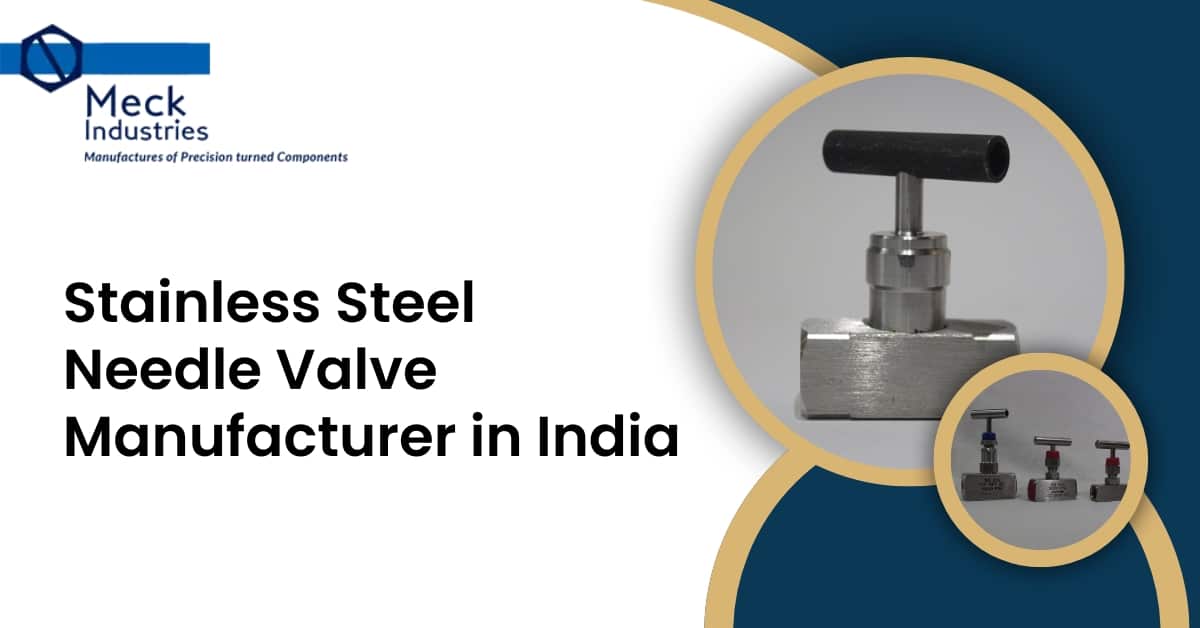

In many industrial systems, precision and reliability matter more than ever. Stainless steel needle parts—such as those found in needle valve assemblies and other metering devices—play a critical role in controlling fluid or gas flow with high accuracy, durability, and corrosion resistance. Manufacturers like Meck Industries offer custom CNC-machined stainless steel needle components crafted for demanding applications across oil & gas, instrumentation, chemical processing, power plants and more.

Why Stainless Steel is the Material of Choice for Needle Parts?

Exceptional Corrosion & Wear Resistance

Stainless steel grades like 304 and 316 are frequently used for needle valve bodies and stems because of their superior resistance to corrosion, oxidation, and wear—even in harsh environments.

Precision Flow Control

Needle-type mechanisms rely on a slender, tapered stem (needle) moving into a matching seat to achieve extremely fine regulation of flow, making precision machining of stainless steel essential.

High Pressure & Temperature Capabilities

Stainless steel needle parts are designed to operate under high pressures (e.g., up to thousands of psi) and wide temperature ranges, making them suitable for severe-service applications.

Key Applications of Stainless Steel Needle Parts

| Application Sector | Use of Stainless Steel Needle Parts | Benefits |

| Oil & Gas / Petrochemical | Needle valves controlling flow of gases, hydrocarbons, instrument lines | Leak-tight shutoff, corrosion resistance |

| Chemical & Process Industry | Flow metering of aggressive chemicals, steam, high temp fluids | High durability, chemical compatibility |

| Instrumentation & Test Systems | Precise flow control for calibration units, instrumentation lines | Fine adjustment, repeatability |

| Power Plants & Utilities | Steam/condensate lines, instrumentation feed lines | High pressure rating, resistant to fouling |

| Marine & Offshore | Needle components in salty, marine environments | Excellent corrosion resistance in saltwater |

Typical Stainless Steel Needle Parts and Their Features

- Needle Stem & Seat Assemblies: The core precision components; stainless steel construction ensures minimal wear and repeated accuracy.

- Needle Valve Bodies / Bonnet: Often forged or bar-stock stainless steel, designed for high-pressure service and durability.

- Threaded Needle Inserts / Connections: Precision machined stainless steel parts that integrate into larger assemblies, providing fine control and long service life.

- Precision CNC-Machined Needle Components: High-tolerance needle parts manufactured by specialist firms like Meck Industries to meet OEM specs and industry standards.

Looking for precision-engineered needle parts for your next project? Contact us today to get high-quality, custom stainless steel needle components designed for your specific industrial needs.

What to Consider When Using Stainless Steel Needle Parts

Material Grade & Specification

Choose the correct stainless steel grade (304, 316, 316L) depending on media, temperature, and corrosion exposure.

Precision & Tolerances

These parts demand tight machining tolerances for proper sealing and control. Surface finish, stem-seat clearance and geometry are critical.

Pressure & Temperature Ratings

Ensure components match the required service conditions—many stainless steel needle parts are rated for thousands of psi and extreme temperatures.

Maintenance & Lifecycle

Stainless steel needle parts reduce maintenance frequency due to their durability. However, proper installation, cleaning and inspection still matter.

OEM & Custom Requirements

For specialized applications (marine, chemical, offshore), custom stainless steel needle parts engineered by experienced manufacturers are often required.

Why Choose Custom Stainless Steel Needle Parts from Meck Industries?

- In-house CNC capability: Precision machining of stainless steel for components such as needle stems, seats and valve bodies.

- Material expertise: Experience with stainless steel grades suited for instrumentation, chemical and high-pressure systems.

- Quality assurance: Calibration, inspection and compliance with industry standards.

- Customized solutions: Ability to deliver tailor-made needle parts for OEMs and high-spec industrial systems.

- Material durability & service life: Components built for longevity in demanding conditions, which means lower total cost of ownership.

Frequently Asked Questions

What advantages do stainless steel needle parts have over brass or carbon steel?

Stainless steel offers superior corrosion resistance, higher strength at elevated temperatures and better durability in harsh environments.

Are stainless steel needle parts suitable for high-pressure valves?

Yes. Many are rated up to several thousand psi and are used in instrumentation and severe-service applications.

Can custom stainless steel needle parts be made for unique OEM applications?

Yes. Experienced manufacturers offer CNC-machined, custom parts engineered to the exact specs and service conditions required.

What industries commonly use stainless steel needle parts?

Oil & gas, chemical processing, marine/offshore, power generation, instrumentation and test systems.

Conclusion

Stainless steel needle parts are foundational components in any system requiring precise flow control, high durability and reliable performance—even under severe conditions. Whether it’s instrumentation, high-pressure industrial flow control or marine applications, choosing the right stainless steel components is essential for efficiency, safety and longevity.

By partnering with a specialist manufacturer like Meck Industries, you gain access to custom CNC-machined stainless steel needle parts built to meet your exact application requirements, backed by material expertise, quality assurance and industry-grade performance.