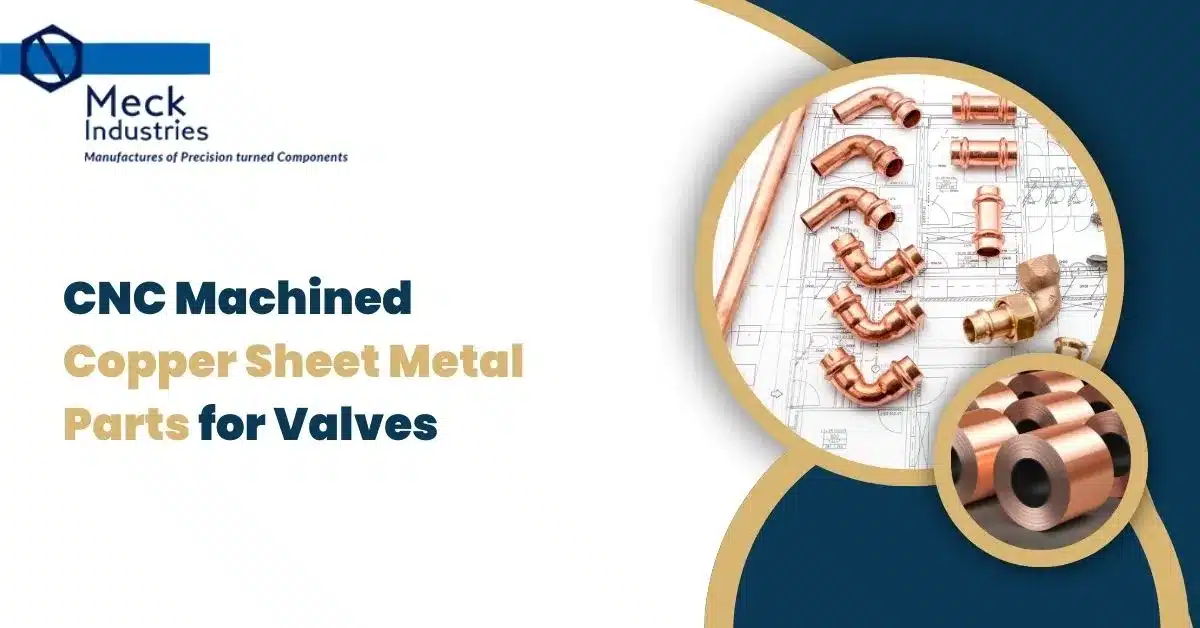

In modern manufacturing, CNC machined copper sheet metal parts play a vital role in ensuring the reliability and efficiency of industrial valve systems. With their excellent electrical and thermal conductivity, corrosion resistance, and precision machinability, copper components are increasingly used in valve manufacturing for industries like oil & gas, plumbing, HVAC, automotive, and power generation.

At Meck Industries, we specialize in producing custom CNC machined copper sheet metal parts for valves, designed to meet OEM requirements and global quality standards.

Why Use Copper Sheet Metal Parts in Valves?

Valves require materials that can withstand pressure, temperature changes, and continuous operation. Copper stands out due to its unique properties:

- High Thermal Conductivity – Prevents overheating in high-pressure valve applications.

- Excellent Corrosion Resistance – Ensures long-term durability even in harsh environments.

- Malleability and Machinability – Enables complex, precise CNC machining for valve components.

- Sustainability – Copper is recyclable, making it an eco-friendly option.

CNC Machining in Copper Valve Components

CNC (Computer Numerical Control) machining allows for high accuracy, consistency, and customization when producing copper sheet metal valve parts. Using advanced CNC machines, manufacturers can deliver components with tight tolerances, ensuring leak-proof performance in valve assemblies.

Advantages of CNC Machining Copper Sheet Metal Parts

- Precision manufacturing with minimal errors.

- Ability to create complex valve designs.

- Faster production cycles with repeatable quality.

- Customization for OEM-specific applications.

Types of CNC Machined Copper Sheet Metal Valve Parts

| Component | Application in Valves | Key Benefits |

| Copper Discs | Used in sealing mechanisms | High corrosion resistance, durability |

| Copper Bushings | Provide support for moving valve parts | Wear-resistant, long-lasting |

| Copper Contacts | For electrically controlled valves | High conductivity, reliable switching |

| Copper Washers & Gaskets | Ensure leak-proof valve assemblies | Precise fit, heat resistance |

| Copper Inserts | OEM valve customization | Flexible design, long lifespan |

Applications of Copper Sheet Metal Parts in Valve Manufacturing

Copper components are widely used across industries that rely on valves for fluid and gas control:

- Oil & Gas Valves – For high-pressure, corrosive environments.

- Automotive Valves – For fuel injection and cooling systems.

- HVAC Systems – For heating and cooling control.

- Plumbing & Water Supply – Leak-proof, corrosion-resistant valve parts.

- Power Generation – High-performance valves in turbines and boilers.

Looking for custom CNC machined copper sheet metal parts for valves? Contact us today for precision-engineered solutions tailored to your OEM needs.

Benefits of CNC Machined Copper Sheet Metal Parts for Valves

- Leak-Proof Sealing – Precision CNC machining ensures tight fits and secure sealing.

- Enhanced Durability – Copper’s resistance to corrosion extends valve life.

- Improved Efficiency – Copper’s conductivity enhances performance in thermally regulated valves.

- Cost-Effective Manufacturing – Durable copper components reduce replacement and maintenance costs.

- Custom OEM Solutions – Designed according to specific industry or client needs.

Why Choose Meck Industries for Copper Valve Components?

- Precision CNC Machining for consistent, high-quality parts.

- Custom Manufacturing to meet OEM valve designs.

- Quality Control & Testing ensuring zero-defect products.

- Industry Experience in serving automotive, oil & gas, and electrical sectors.

- Sustainability Commitment with eco-friendly copper solutions.

Frequently Asked Questions

Why is copper used in valve manufacturing?

Copper’s conductivity, corrosion resistance, and machinability make it ideal for reliable and long-lasting valve components.

Do you provide custom CNC copper parts for OEMs?

Yes, we manufacture custom valve parts as per OEM requirements and technical drawings.

Are copper parts suitable for high-pressure valves?

Absolutely. CNC machined copper components ensure durability and leak-proof performance in high-pressure environments.

Can copper valve components be coated or plated?

Yes, they can be tin, nickel, or silver plated for added durability and performance.

Conclusion

CNC machined copper sheet metal parts are an essential component in valve manufacturing, providing precision, durability, and efficiency across industries. By choosing a trusted partner like Meck Industries, OEMs and manufacturers can ensure high-quality copper components that enhance valve performance and reliability.