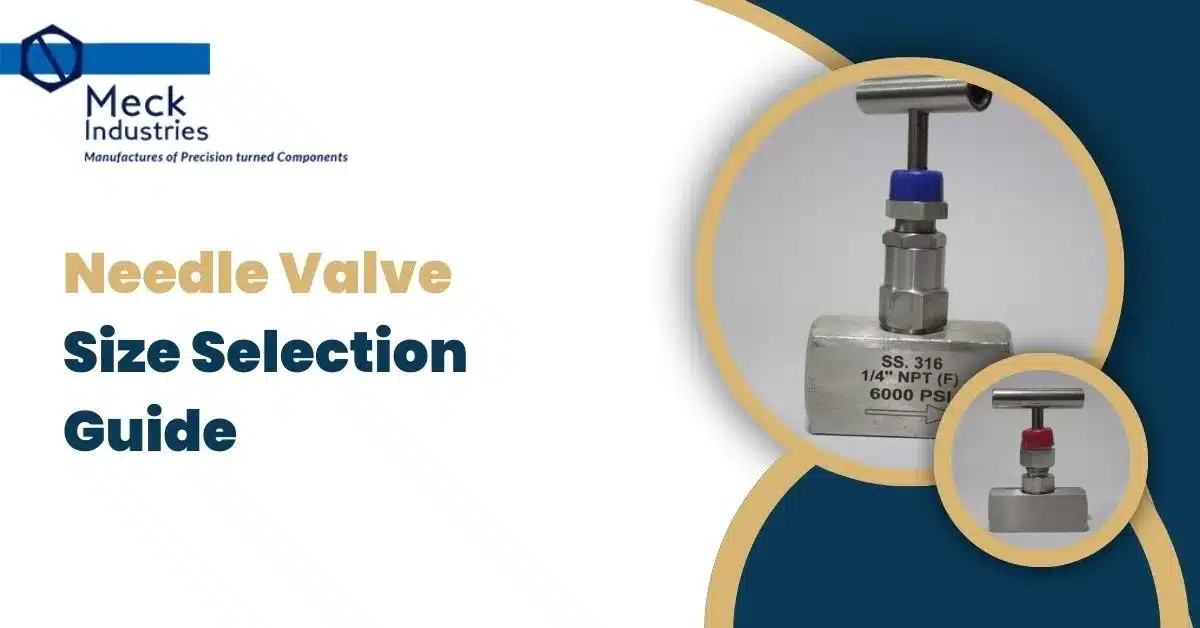

Selecting the correct needle valve size is critical for achieving precise flow control, system safety, and long-term performance in industrial applications. An incorrectly sized needle valve can lead to flow instability, leakage, excessive pressure drops, or premature valve failure. This needle valve size selection guide will help engineers, maintenance teams, and procurement professionals understand how to choose the right needle valve based on application requirements, operating conditions, and industry standards.

What is a Needle Valve?

A needle valve is a precision flow control valve designed to regulate small flow rates with high accuracy. It uses a slender, tapered needle-like stem that fits into a matching seat, allowing gradual and fine adjustment of fluid or gas flow. Needle valves are widely used in gas handling systems, hydraulic circuits, instrumentation lines, and high-pressure applications where controlled flow is essential.

Why Needle Valve Size Selection Is Important?

Proper needle valve sizing ensures optimal system performance and operational safety. Choosing the correct size helps:

- Maintain accurate flow control

- Prevent pressure loss and flow restriction

- Reduce wear on valve components

- Improve sealing efficiency

- Enhance system reliability and service life

Incorrect sizing can result in excessive throttling, vibration, noise, or leakage, which may damage connected equipment and compromise safety.

Key Factors to Consider for Needle Valve Size Selection

1. Flow Rate Requirement

The first step in needle valve size selection is determining the required flow rate. The valve size must be capable of handling the desired flow without excessive pressure drop while still allowing precise control at low flow conditions.

2. Operating Pressure

Needle valves are commonly used in low to high-pressure systems. Always select a valve size that can safely handle the maximum operating pressure of your application to avoid deformation or failure.

3. Fluid or Gas Type

The type of media flowing through the valve plays a major role in size selection. Gases, liquids, corrosive fluids, or viscous media may require different valve sizes and materials to ensure compatibility and performance.

4. Temperature Conditions

Operating temperature affects material strength and sealing performance. Ensure the selected needle valve size and material are suitable for the minimum and maximum temperature limits of your system.

5. Connection Size and Type

Needle valve size should match the pipeline or tubing size to avoid unnecessary adapters or flow restrictions. Common connection types include threaded, compression, and socket weld fittings.

6. CV Value (Flow Coefficient)

The CV value indicates how much flow a valve can pass at a given pressure drop. Selecting a needle valve with an appropriate Cv value ensures controlled flow without excessive pressure loss.

Looking for the right needle valve size for your application? Contact us now!

Common Needle Valve Sizes and Applications

Common needle valve sizes and applications vary by industry, but each size is designed to deliver precise flow control, leak-free operation, and reliable performance in fluid and gas handling systems.

| Needle Valve Size | Typical Applications |

| 1/8 inch | Instrumentation, calibration systems |

| 1/4 inch | Gas handling, laboratory equipment |

| 3/8 inch | Hydraulic control, industrial panels |

| 1/2 inch | Process control, high-pressure systems |

| 3/4 inch – 1 inch | Heavy-duty industrial applications |

Needle Valve Size Selection Process

The needle valve size selection process involves evaluating flow rate requirements, operating pressure, fluid type, temperature, and connection size to ensure precise control, safety, and optimal system performance.

- Identify the system flow rate and pressure requirements.

- Determine the type of fluid or gas being controlled.

- Check temperature and environmental conditions.

- Calculate or verify the required Cv value.

- Match the valve size with pipeline or tubing dimensions.

- Select a high-quality needle valve manufactured to industry standards.

Following this structured approach ensures accurate needle valve size selection for reliable and efficient operation.

Common Mistakes in Needle Valve Size Selection

Common mistakes in needle valve size selection include ignoring flow rate requirements, overlooking pressure and temperature limits, mismatching connection sizes, and choosing valves without considering the application’s control precision and safety needs.

- Oversizing the valve, leading to poor flow control

- Ignoring pressure and temperature limits

- Selecting the wrong material for the media

- Not considering future system expansion

- Choosing size based only on pipe diameter

Avoiding these mistakes helps improve performance and reduces maintenance costs.

Applications That Require Accurate Needle Valve Sizing

Applications that require accurate needle valve sizing include gas handling systems, hydraulic and pneumatic circuits, chemical processing, laboratory instruments, and high-pressure industrial systems where precise flow control and safety are critical

Precise needle valve size selection is essential in:

- Gas handling and distribution systems

- Hydraulic and pneumatic circuits

- Electrical switchgear assemblies

- Chemical and process industries

- Automotive and industrial testing equipment

Why Choose Precision Needle Valves from Meck Industries?

Meck Industries manufactures precision-engineered needle valves using advanced CNC machining and strict quality control practices. Our needle valves are designed to deliver accurate flow regulation, high-pressure resistance, and long service life across demanding industrial applications. With expertise in ferrous and non-ferrous machining, we provide reliable solutions tailored to customer requirements.

Frequently Asked Questions

How do I know what size needle valve I need?

You need to consider flow rate, pressure, media type, temperature, and Cv value to determine the correct needle valve size

What happens if a needle valve is oversized?

An oversized needle valve can cause poor flow control, vibration, and difficulty in achieving precise adjustments

Are needle valves suitable for high-pressure applications?

Yes, needle valves are ideal for high-pressure systems when properly sized and manufactured from suitable materials

Can needle valve size affect system safety?

Yes, incorrect needle valve sizing can lead to leakage, pressure imbalance, and potential system failure

Conclusion

Selecting the right needle valve size is essential for achieving precise flow control, maintaining system safety, and extending equipment life. By considering factors such as flow rate, pressure, temperature, media type, and Cv value, you can make informed decisions and avoid common sizing mistakes. A well-chosen needle valve ensures efficient operation and reliable performance across industrial applications