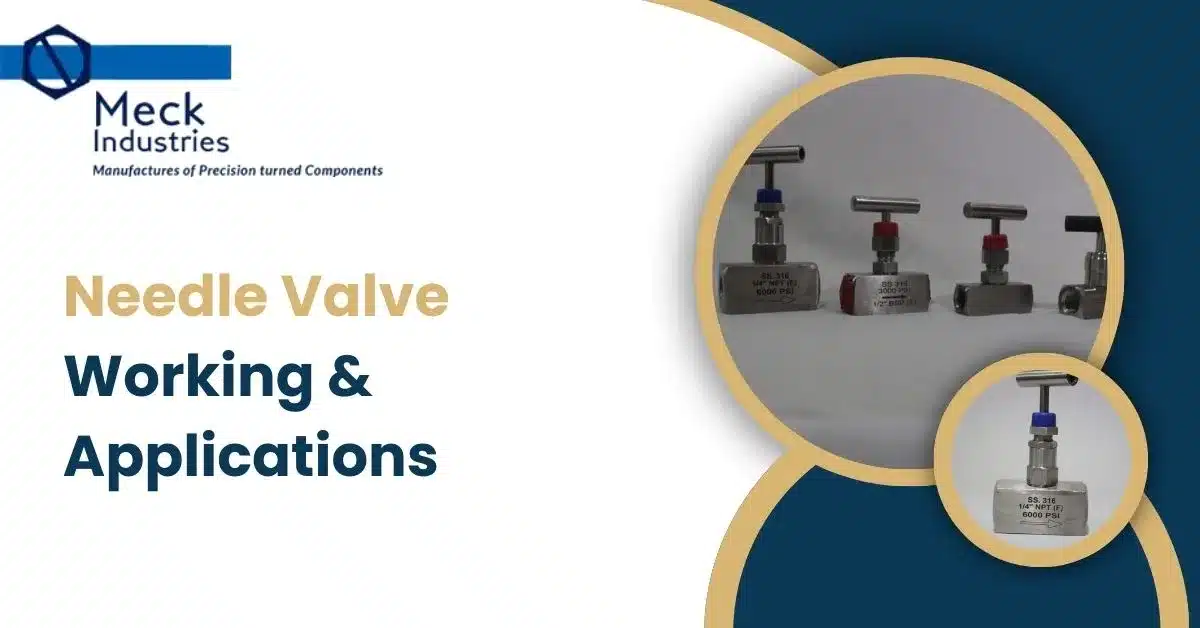

Precise flow control plays an essential role in laboratory instruments, industrial systems, and fluid control operations, and that is where the Needle Valve proves to be a highly reliable solution. At Meck Industries, we manufacture high-precision Needle Valve components designed for accurate regulation, smooth operation, and long-term durability in demanding environments.

How Needle Valve Works?

A Needle Valve operates using a fine-tapered needle-shaped plunger that moves inside a precision-machined seat, enabling highly accurate control of liquid or gas flow. The Needle Valve stem is threaded to allow gradual lifting or lowering of the needle, which ensures smooth flow adjustment without sudden pressure fluctuations. The leak-tight sealing ability of a Needle Valve makes it ideal for sensitive flow systems where accuracy is crucial.

Key Working Features of a Needle Valve

- The Needle Valve uses a conical needle and seat arrangement for controlled flow.

- Fine threads allow the Needle Valve to provide incremental flow adjustment.

- A Needle Valve offers complete shut-off capabilities when fully closed.

- Industrial systems depend on a Needle Valve for reliable pressure management.

Applications of Needle Valve

Across industries, the Needle Valve is chosen for operations where precise flow measurement and regulation must be maintained. Whether in research laboratories, fluid instrumentation, test benches, or automation equipment, the Needle Valve ensures accurate control with minimal leakage. The versatility of a Needle Valve allows use with liquids, gases, oils, chemicals, and steam.

| Industry / Equipment Type | Role of Needle Valve |

| Laboratory Instruments | The Needle Valve regulates chemical and gas flow in testing equipment |

| Fluid Process Lines | The Needle Valve ensures precise control in pipelines and control panels |

| Hydraulic & Pneumatic Systems | The Needle Valve helps manage actuator and pump flow |

| Instrumentation Systems | The Needle Valve stabilizes pressure for gauges and measurement sensors |

| OEM Industrial Machines | Custom Needle Valve design supports equipment performance |

Advantages of Needle Valve

Every Needle Valve is CNC-machined to maintain tight tolerances and leakage-free operation. Designed for durability and efficiency, the Needle Valve provides superior performance under varying temperature and pressure conditions. The customizable design options available for a Needle Valve make it suitable for diverse OEM applications requiring precision.

Key Benefits of Needle Valve

- High accuracy flow control with a precision Needle Valve

- Long-term corrosion resistance and durability in every Needle Valve

- Custom sizes, threads, and sealing options available for each Needle Valve

- Leak-proof structure ensures safe system performance for the Needle Valve

Looking for a high-precision Needle Valve for demanding applications? Contact us to discuss custom Needle Valve solutions or request a quote today.

Best Practices for Needle Valve Performance

To achieve maximum reliability, proper handling and installation of a Needle Valve is essential. When adjusting the Needle Valve, slow rotation helps prevent sudden flow or pressure surges. It is important to choose a Needle Valve with material suitable to the type of fluid or gas to avoid corrosion and wear. Periodic inspection ensures the Needle Valve continues to operate smoothly.

Frequently Asked Questions

What is a Needle Valve and why is it preferred in fluid control?

A Needle Valve uses a tapered needle and seat to allow precise, incremental control of flow, making it ideal for applications requiring accurate regulation of liquids or gases.

Can Meck Industries supply custom Needle Valve sizes and configurations?

Yes — Meck Industries offers custom Needle Valve manufacturing with specific dimensions, thread types, sealing surfaces, and material choices as per client requirements.

What media can a Needle Valve handle safely?

Depending on the material specification, a Needle Valve from Meck Industries can safely handle fluids, gases, oils, and even mild corrosive media (with proper material selection).

How do I ensure leak-proof sealing and smooth operation of a Needle Valve?

Proper installation, correct material selection, and periodic inspection are key. Slow stem adjustment and clean installation help maintain smooth operation and leak-free sealing.

Are Needle Valves suitable for both low-flow and high-pressure systems?

Yes. Needle Valves from Meck Industries are designed to deliver precise control at low flow rates and can be engineered for high-pressure applications as per specifications.

Conclusion

The Needle Valve is one of the most precise and dependable flow control components used in laboratory systems, industrial automation, and fluid handling applications. At Meck Industries, each Needle Valve is engineered with performance, precision, and longevity in mind, enabling smooth and accurate flow regulation across multiple industries. If you need reliable flow control, the Needle Valve from Meck Industries is the perfect choice.